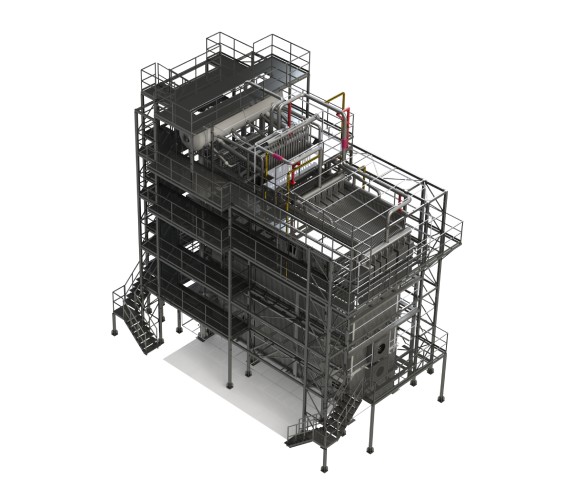

Water Tube Boiler

Description

A water tube boiler is a type of boiler where water circulates in tubes that are heated externally by the combustion gases. This design is opposite to that of a fire tube boiler, where hot gases pass through tubes submerged in water. Here are some key features and advantages of water tube boilers:

Water-Tube Boilers:

- Design: Water circulates through tubes heated by combustion gases.

- Advantages: High efficiency and capable of producing high steam pressures.

- Applications: Typically used in large-scale industrial applications.

Specifications

Key Features:

- Design: The boiler consists of a series of water-filled tubes that are surrounded by the hot gases produced by burning fuel.

- Heat Transfer: The high surface area of the tubes allows for efficient heat transfer, enabling the boiler to produce steam quickly.

- Pressure Capacity: Water tube boilers can operate at higher pressures and temperatures than fire tube boilers, making them suitable for industrial applications.

- Efficiency: They typically have higher thermal efficiency due to better heat transfer characteristics and the ability to recover heat from flue gases.

Advantages:

- Compact Size: Water tube boilers are generally more compact and lighter than fire tube boilers.

- Rapid Response: They can respond quickly to changes in steam demand, making them ideal for applications with fluctuating load conditions.

- Safety: In the event of a malfunction, the risk of a catastrophic failure is lower because of the smaller volume of water contained in the tubes.

- Fuel Flexibility: Many water tube boilers can accommodate various types of fuels, including natural gas, oil, and biomass.

Applications:

Water tube boilers are widely used in power plants, chemical plants, and large industrial facilities, where they provide steam for power generation, heating, and various processes.