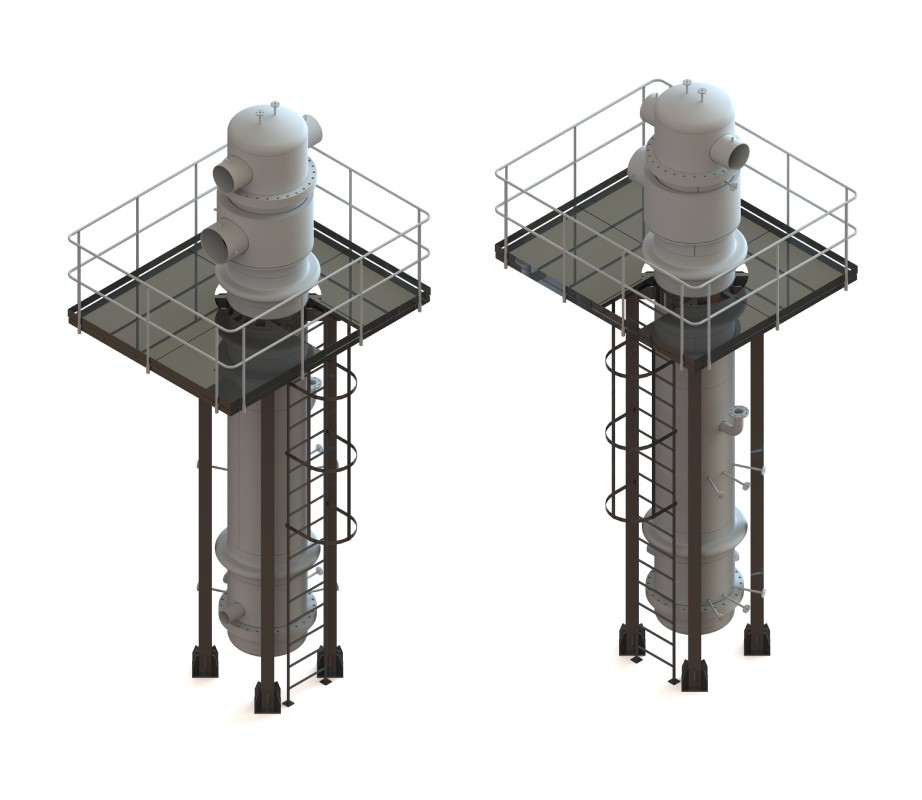

Boiler Desuperheating Station

Description

A boiler desuperheating station is designed to reduce the temperature of superheated steam to a desired level, making it suitable for various industrial applications. Here’s a breakdown of its components, functions, and applications:

Key Components

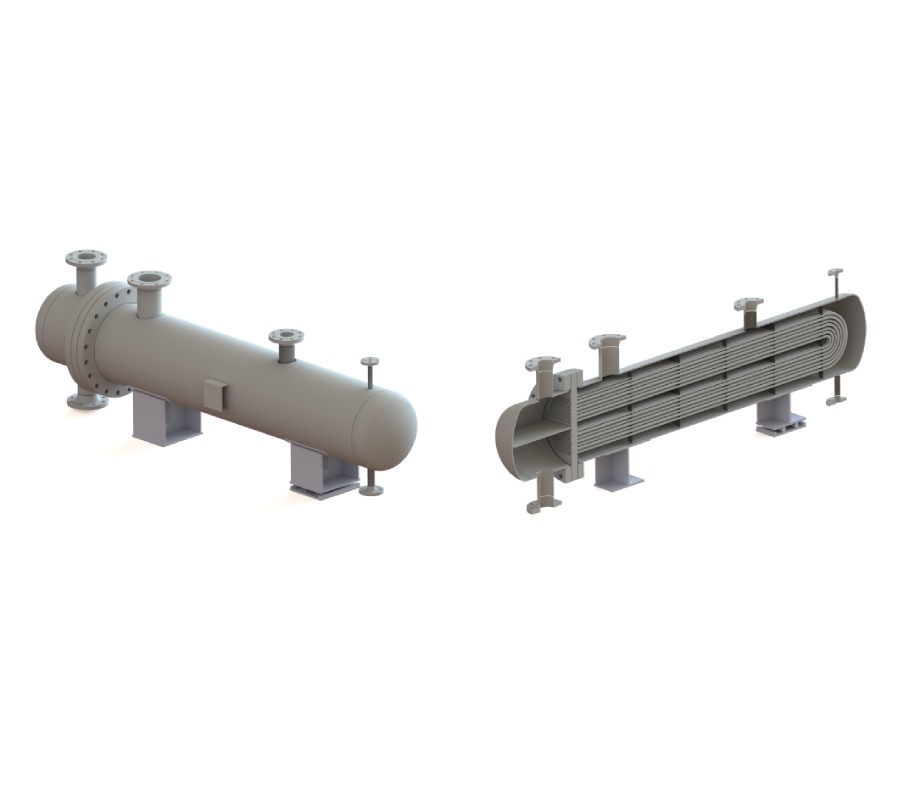

- Desuperheater: The main device that cools the superheated steam. It typically uses water sprays or a heat exchanger.

- Control Valves: Regulate the flow of water and steam, ensuring optimal mixing and temperature control.

- Temperature Sensors: Monitor the steam temperature to ensure it meets specified requirements.

- Pressure Gauges: Provide real-time pressure readings of the steam before and after desuperheating.

- Flow Meters: Measure the flow rates of steam and cooling water.

Specifications

Functions

- Temperature Control: Reduces the steam temperature to a set point, preventing damage to downstream equipment.

- Steam Quality Improvement: Ensures steam is at the correct temperature for efficient energy transfer in processes.

- Safety: Helps prevent overtemperature conditions that could lead to equipment failure or safety hazards.

Applications

- Power Generation: In power plants, desuperheating steam is essential for turbines and other equipment.

- Chemical Processing: Used in various chemical manufacturing processes where specific steam temperatures are required.

- Food and Beverage Industry: Maintains safe steam temperatures for sterilization and cooking processes.

Maintenance

Regular maintenance is important to ensure efficient operation. This includes:

- Inspecting desuperheaters for wear and tear

- Calibrating temperature sensors and control valves

- Checking for blockages in piping or spray nozzles